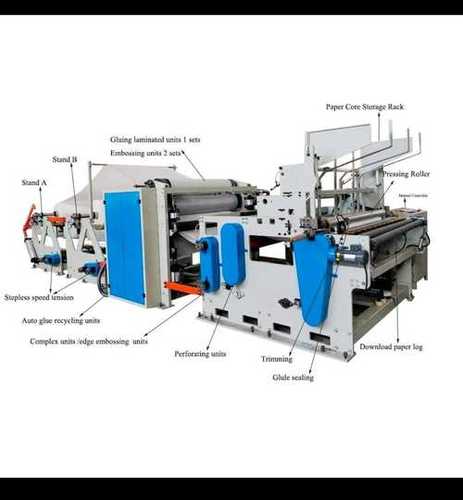

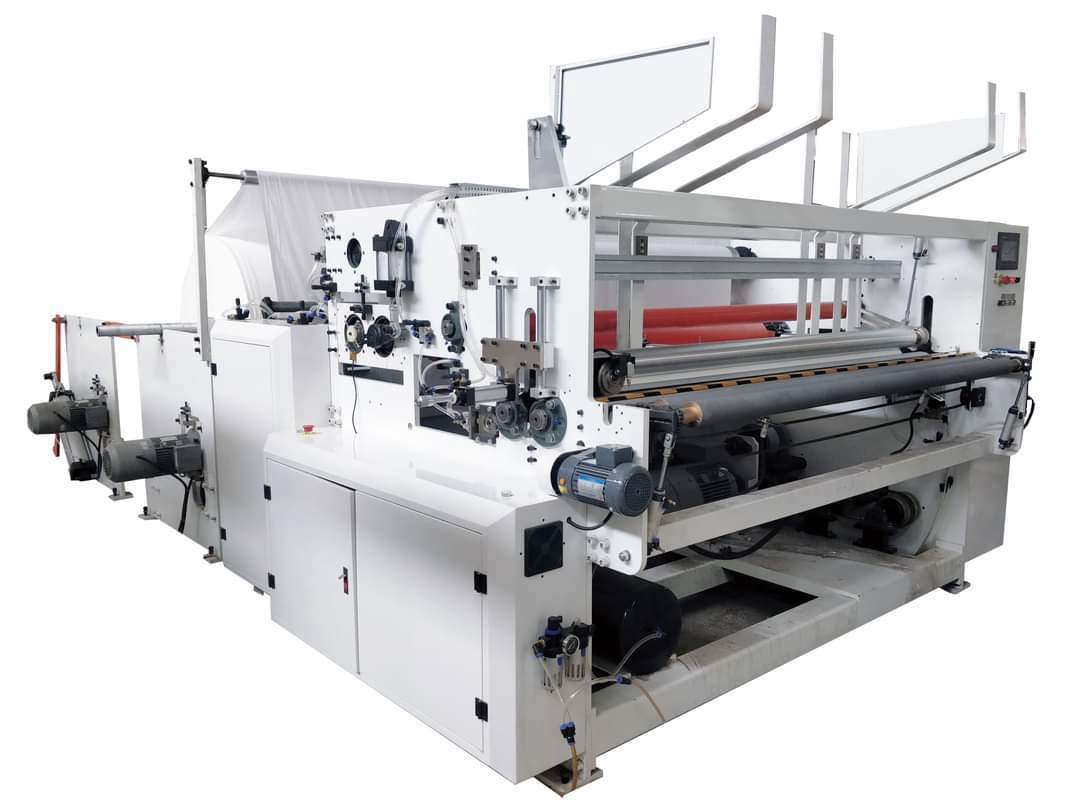

Automatic Toilet Roll Log Rewinding Machine

Product Details:

- Material Stailness Steel

- Computerized No

- Voltage 220 Volt (v)

- Click to view more

Automatic Toilet Roll Log Rewinding Machine Price And Quantity

- 1 Unit

- 550000.00 - 1350000.00 INR/Container

- 550000 INR/Container

Automatic Toilet Roll Log Rewinding Machine Product Specifications

- 220 Volt (v)

- No

- Stailness Steel

Automatic Toilet Roll Log Rewinding Machine Trade Information

- 4 Unit Per Month

- 45 Months

- All India

Product Description

Owing to our proficiency in this domain, we have been able to manufacture, export and supply high quality Toilet Roll Automatic Machine that is meant for manufacturing toilet paper and various other kinds of tissue paper. Offered machine is manufactured by our professionals as per the set industry standards using high grade parts. Owing to its unmatched features and optimum quality, the offered Toilet Roll Log Rewinding Automatic Machine is highly demanded in the market. This machine is available in various technical specifications to meet the diverse needs of the clients.

Features:

- Sturdy construction

- Easy installation

- Smooth operation

- Minimum maintenance

|

Maximum Paper Width |

1350/1450/1650/1850/2250/ or as per require |

|

Maximum unwind diameter |

1200mm |

|

Maximum rewinding diameter |

120mm |

|

Jumbo Roll Stand |

1 Stands Standard Extra (As per requirement) |

|

Parent roll core inner dia. |

76mm |

|

Raw paper material |

13-16 g/m2, Lifted by Pneumatic Loading |

|

Unwind unit |

One |

|

Capacity/8 hr |

100m/min 8000-15000 Rolls |

|

Perforation repeat |

115mm |

|

Embossing unit |

ONE (Steel to rubber type) |

|

Power required(Air System) |

5 H.P. 380 v 440 V 3 Ph. 50 Hz |

|

Main transmission |

Variable Frequency speed regulating |

|

Data Setting |

HMI |

|

Control |

PLC Drive (Touch Screen) |

|

Finished Log Outer Diameter |

100-120-150 |

|

Finished Log Inner Diameter |

38-45-50-60 |

|

Diameter of Finished Log Control |

By Electronic/ Air Control |

|

Main Driving |

Frequency conversion speed regulation 9KW 380V, 50HZ |

|

Weight |

2500 kg -5000kg Appx.(Depends on Machine Size) |

|

Space required |

7'x7'x6' (L xW x H).(Depend on Machine Size) |

|

End product specification |

Each logs of 100 gms with each sheet length of 110mm |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+